and did my project slip.

I had planned on putting in a full day at the office and then do some work on the house tonight.

Well, I received a call that the Van was overheating so I had to leave the office early and get the car in the shop, then that shop called and said it was an electrical issue and I had to find another shop to repair it.

Now, instead of working on the house, I'm working on my job.

P.S. As I walked through a tiled hall at work this morning, I kept noticing that the corners of the tiles were slightly mis-aligned, you know, an 1/8th of an inch or so. Man, I'm warped.

Our home is due for a makeover. Read along as we go through the process.

Thursday, August 30, 2007

Wednesday, August 29, 2007

And on the 43rd day, John rested

I took the day off from the office and read a book all morning.

Well, I returned the rental tools, but no actual work took place...

Well, I returned the rental tools, but no actual work took place...

Flooring Finished, now it's time to wrap it up!

The three boxes of flooring that I ordered yesterday did arrive here on time for me to pick them up on the way home from work and I was able to finish installing the flooring.

Before we installed any flooring tonight, we folded back the tar paper and wrote on the plywood underlayment "Joshua 24:15 As for me and my house we will serve the Lord" directly under the entryway flooring. I realized to late that I should have taken a picture.

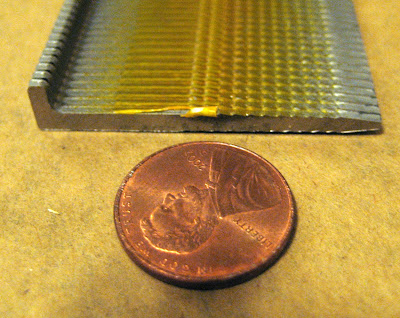

My son was a really good helper tonight, he made sure I had boards and tools and we were finished with the "easy" stuff by about 9PM. However when I got over to the corner where the two doors are and it was the last run, it got a little interesting. I thought I had layed out the first run of flooring in the kitchen such that I would end up with 2-1/2 inches to install on the other end. I ended up with about 1/2 inch. Either we accumulated 2 inches of slack over 33 feet, or I miscalculated. Given my recent bouts with mis-calculations, I am going to go with that. I had to rip down a five inch wide board to 11/16ths or smaller in some cases. I took a picture and enhanced the contrast and color to show the very small section left, the full size plank is five inches.

At first I thought I might be able to get away without a small board at the end, but as you can see in the next picture, the quarter-round molding just doesn't cover out that far.

This shows what it will look like once it is installed. I have to wait on installing the molding, since I made a mistake on painting the gap. I used Semi-Gloss instead of a flatter paint for the wall. So I need to go back to Home Depot and ask for the same color, just in a flat paint that I can use on the walls, then install the molding. Once that's done, we can start putting on the felt pads for the different furniture, including the piano, and get our living room back in order. My wife did a great job straightening up the kitchen today, since all of the appliances were hooked up and I was out of the way with tools etc.

I intentionally bought one extra box for future needs, but I think I may have bought too much, since I had quite a few boards left over. It is hard to tell exactly how much material you are going to need since you end up cutting away excess material on the ends many times.

Now I need to wrap those boards up tight in something, as well as the box on the floor, and put them in the garage somewhere for some future owner that wishes to repair something, or add on. We may even extend this flooring down the hallway, since the carpet there is in pretty bad shape as well.

I'm taking the day off from work tomorrow, I think I'll read a book (not a home improvement book)

Before we installed any flooring tonight, we folded back the tar paper and wrote on the plywood underlayment "Joshua 24:15 As for me and my house we will serve the Lord" directly under the entryway flooring. I realized to late that I should have taken a picture.

My son was a really good helper tonight, he made sure I had boards and tools and we were finished with the "easy" stuff by about 9PM. However when I got over to the corner where the two doors are and it was the last run, it got a little interesting. I thought I had layed out the first run of flooring in the kitchen such that I would end up with 2-1/2 inches to install on the other end. I ended up with about 1/2 inch. Either we accumulated 2 inches of slack over 33 feet, or I miscalculated. Given my recent bouts with mis-calculations, I am going to go with that. I had to rip down a five inch wide board to 11/16ths or smaller in some cases. I took a picture and enhanced the contrast and color to show the very small section left, the full size plank is five inches.

At first I thought I might be able to get away without a small board at the end, but as you can see in the next picture, the quarter-round molding just doesn't cover out that far.

This shows what it will look like once it is installed. I have to wait on installing the molding, since I made a mistake on painting the gap. I used Semi-Gloss instead of a flatter paint for the wall. So I need to go back to Home Depot and ask for the same color, just in a flat paint that I can use on the walls, then install the molding. Once that's done, we can start putting on the felt pads for the different furniture, including the piano, and get our living room back in order. My wife did a great job straightening up the kitchen today, since all of the appliances were hooked up and I was out of the way with tools etc.

I intentionally bought one extra box for future needs, but I think I may have bought too much, since I had quite a few boards left over. It is hard to tell exactly how much material you are going to need since you end up cutting away excess material on the ends many times.

Now I need to wrap those boards up tight in something, as well as the box on the floor, and put them in the garage somewhere for some future owner that wishes to repair something, or add on. We may even extend this flooring down the hallway, since the carpet there is in pretty bad shape as well.

I'm taking the day off from work tomorrow, I think I'll read a book (not a home improvement book)

Tuesday, August 28, 2007

Monday Progress - 48 square feet to go!

I am almost done putting down the flooring in the living room.

My pastor called this morning and said "If you're not done, I'll come over and help. Oh, yes please!" We spent a few hours putting down whatever boards we had left, then moved the appliances back in to the kitchen.

Earlier in the day, I had double checked my measurements and ordered three more boxes (of 23 square feet each) which should arrive tomorrow some time. I hope to put those down tomorrow night and be done with the flooring installation by tomorrow night. However, as my sister kept reminding me, the project isn't done until the molding is placed around the floor. Since the new molding is significantly smaller, it will leave a lot of unpainted wall showing. So, with that in mind, I went out to the garage and found the paint can from 1999 that we used to paint the living room and took it over to Home Depot tonight to have another can made up. Hopefully it's the right stuff because I also used that paint to fix up dings and scratches on other places up the wall. The color seemed to match pretty well, but I am not sure about the gloss factor. I guess I'll find out when it is dry tomorrow night. (Edit: Well, it was the wrong gloss factor, I must have grabbed the can for the trim, not the walls. Guess I get to do some more painting tonight!)

Getting the appliances back in their places should help my wife start to get the kitchen under control again. If you look at the picture above you'll see that there is a lot of stuff on the counter, it all had to come out from under the counter to put the dishwasher back in place. We also spent a little time resetting the leg heights on the stove to get it completely level, both side to side and back to front. My son asked me why this was important, I told him it was so that when we fry bacon, the grease won't all go to one side.

Tuesday is back to work day for me, so I hope that the paint drys, the boards arrive and I can get the flooring installed pretty quickly. Of course, when I get to the end near the front of the house, I can no longer use the cleat driver, but will need to pilot drill and finish nail them in place. It's also harder because I have to rip saw the boards along the last row to fit in whatever space is left. Hopefully it is exactly what we cut off Saturday morning to start the first row in the kitchen, if so I already have the other side cut (probably not)

I put a video of the cleat nailer in action if you wanted to see it.

My pastor called this morning and said "If you're not done, I'll come over and help. Oh, yes please!" We spent a few hours putting down whatever boards we had left, then moved the appliances back in to the kitchen.

Earlier in the day, I had double checked my measurements and ordered three more boxes (of 23 square feet each) which should arrive tomorrow some time. I hope to put those down tomorrow night and be done with the flooring installation by tomorrow night. However, as my sister kept reminding me, the project isn't done until the molding is placed around the floor. Since the new molding is significantly smaller, it will leave a lot of unpainted wall showing. So, with that in mind, I went out to the garage and found the paint can from 1999 that we used to paint the living room and took it over to Home Depot tonight to have another can made up. Hopefully it's the right stuff because I also used that paint to fix up dings and scratches on other places up the wall. The color seemed to match pretty well, but I am not sure about the gloss factor. I guess I'll find out when it is dry tomorrow night. (Edit: Well, it was the wrong gloss factor, I must have grabbed the can for the trim, not the walls. Guess I get to do some more painting tonight!)

Getting the appliances back in their places should help my wife start to get the kitchen under control again. If you look at the picture above you'll see that there is a lot of stuff on the counter, it all had to come out from under the counter to put the dishwasher back in place. We also spent a little time resetting the leg heights on the stove to get it completely level, both side to side and back to front. My son asked me why this was important, I told him it was so that when we fry bacon, the grease won't all go to one side.

Tuesday is back to work day for me, so I hope that the paint drys, the boards arrive and I can get the flooring installed pretty quickly. Of course, when I get to the end near the front of the house, I can no longer use the cleat driver, but will need to pilot drill and finish nail them in place. It's also harder because I have to rip saw the boards along the last row to fit in whatever space is left. Hopefully it is exactly what we cut off Saturday morning to start the first row in the kitchen, if so I already have the other side cut (probably not)

I put a video of the cleat nailer in action if you wanted to see it.

Sunday, August 26, 2007

Sunday Progress - Missed it by that much

I just couldn't go to sleep Saturday night, I just kept thinking about what we were going to do next and how long it would take to get it done. Unfortunately none of my guesses were right, not even how much material we would need.

As the picture shows, we have about half of the living room still to go. I got up plenty early and ran over to Home Depot to pick up some more cleats and some more Tar paper. We didn't want to have to run over there later in the day, since we knew we didn't have enough paper, and we weren't sure if we had enough cleats.

I had decided to skip church in the morning (Yes, I know!) and work until I had to leave for the Sunday night program that I was kicking off that night. If we worked as effectively from 9 AM until 3 PM as we had done in the open area of the kitchen the day before, we'd be almost completely done before I had to leave. Then the phone rang. "I need you to come to church and do sound, so-and-so is out of town and we need you for the service" OK, now I had to leave the house at 10AM and not be back until 11:30AM.

Getting in to the living room required us to bridge the entryway and set a new chalkline for the boards in the living room. It took us quite a while to establish a new line for various reasons, so we didn't really start laying down flooring until just before I had to leave for the morning service. When I got back, we tried to get a few boards in place, but with just the two of us, we weren't moving too fast.

Later in the afternoon, two more of my friends came over and we really started moving fast. However I ran out of time before I had to leave for the sunday night program. Fortunately my sister and another friend stayed for a little while and did a few more rows.

So, sitting here on the couch in the living room I can see that we have about 7 feet 7 inches to go which (when multiplied by 18) is 136 square feet left. Unfortunately I only have 104 square feet of material left! Somewhere along the line, the guy at the store thought I had 500 square feet of flooring that I needed. Yesterday I realized that I didn't have enough plywood to cover the floor, that should have been my first clue. We didn't really scrap THAT much of the plywood, so I couldn't figure out how we had been three full sheets short. We had ordered 10% overage on the flooring, so I purchased 552 square feet. Turns out I needed about 580 to 590.

So, tomorrow I finish installing what I have, get a good measurement, and order at least two, maybe four boxes of material (to have enough variety) then rent what I need to finish the job another day this week, since it takes a few days for delivery.

Ugh, I'm frustrated right now!

As the picture shows, we have about half of the living room still to go. I got up plenty early and ran over to Home Depot to pick up some more cleats and some more Tar paper. We didn't want to have to run over there later in the day, since we knew we didn't have enough paper, and we weren't sure if we had enough cleats.

I had decided to skip church in the morning (Yes, I know!) and work until I had to leave for the Sunday night program that I was kicking off that night. If we worked as effectively from 9 AM until 3 PM as we had done in the open area of the kitchen the day before, we'd be almost completely done before I had to leave. Then the phone rang. "I need you to come to church and do sound, so-and-so is out of town and we need you for the service" OK, now I had to leave the house at 10AM and not be back until 11:30AM.

Getting in to the living room required us to bridge the entryway and set a new chalkline for the boards in the living room. It took us quite a while to establish a new line for various reasons, so we didn't really start laying down flooring until just before I had to leave for the morning service. When I got back, we tried to get a few boards in place, but with just the two of us, we weren't moving too fast.

Later in the afternoon, two more of my friends came over and we really started moving fast. However I ran out of time before I had to leave for the sunday night program. Fortunately my sister and another friend stayed for a little while and did a few more rows.

So, sitting here on the couch in the living room I can see that we have about 7 feet 7 inches to go which (when multiplied by 18) is 136 square feet left. Unfortunately I only have 104 square feet of material left! Somewhere along the line, the guy at the store thought I had 500 square feet of flooring that I needed. Yesterday I realized that I didn't have enough plywood to cover the floor, that should have been my first clue. We didn't really scrap THAT much of the plywood, so I couldn't figure out how we had been three full sheets short. We had ordered 10% overage on the flooring, so I purchased 552 square feet. Turns out I needed about 580 to 590.

So, tomorrow I finish installing what I have, get a good measurement, and order at least two, maybe four boxes of material (to have enough variety) then rent what I need to finish the job another day this week, since it takes a few days for delivery.

Ugh, I'm frustrated right now!

Saturday Progress - Half way

I'm writing this on Sunday night since we haven't had the internet connected for 48 hours. I am going to summarize the Saturday progress and then write another post for Sunday.

The plywood installation completed Saturday morning about 11AM. We had to buy some more plywood, because we just didn't have enough. It turned out that we needed three additional 4x8 sheets of plywood, we originally had 16 making the total 19 sheets used, with a little wasted material trying to fit in special areas etc. (This will be important later, note the foreshadowing)

I uploaded a video of the plywood underlayment stapler in action.

After we completed stapling down the plywood, we put down the tar paper for a moisture barrier. Apparently it also acts to quiet the floor some as well. It is a piece of kraft paper, a layer of tar, and another piece of kraft paper. When you look at the floor in progress pictures, you'll see a greenish/brown paper laying on the plywood underlayment. It is four feet wide and we put down one line of it to start.

The most drawn out part of the day was getting the proper initial measurements to set the first line of boards. Over and over it is emphasized to not use the wall as a guide, rather find a couple of places along the wall and measure out 1/2 of one board width PLUS a 1/2 inch expansion space. In our case that makes 3 inches. However the wall is not straight, and the sliding glass door is set back a little way from the drywall. We marked a few places, then used a chalkline (had to go buy one since I hadn't asked anyone to bring one of theirs) to snap a straight line as a reference. Since the marked points are from the wavy wall, some of them are inside of the line and some of them are outside of the line. The line is the reference for all of the boards along that first row. We then had to measure the actual width that the first board needed to be. Oh man this took a long time, then we made one wrong and had to do it again. The biggest problem is remembering which edge of the board to measure from since there is a tongue on one side and a groove on the other, you can't just turn them around if you measured wrong.

Eventually we had a board cut to the right dimensions to attach it to the floor. Since the first run is usually two or three inches from the wall, the special air-powered wood floor cleat nailer was too big to get in and be used. We had to pilot drill and hammer in 1-1/2" finishing nails. The pilot drill was a nail with the head cut off. Once the first board was nailed down, we could move on to the board next to it. Again, since the wall is wavy, we had to measure again to be sure that the board would end up with about 1/2" clearance from the wall. This space gets covered by "quarter-round" molding eventually. This proceeded for what must have been an hour, maybe more. It may have taken a while, but it was important not to rush it, as any mistake there would offset the next row etc. etc. so I wanted it to be right.

Once the first row was top-nailed, we could actually start using the cleat nailer. Cleats are like a flat nail with an L shaped head. They are designed to be driven at an angle through the tongue end of the board, between the tongue and the top of the board. This holds it solidly, but can be covered up by the groove of the next board. This leaves no nails on the surface of most of the floor.

Seeing these cleat nails in a row like this reminds me of when I was a kid and my dad and I were at a parking lot with a construction site adding on to the strip mall. We looked on the ground and there was a lot of litter, and in the litter there were these strips of nails, all glued together at an angle. We figured it was trash so we grabbed a few strips and took them home. We had hundreds of these nails, apparently the guys using them just threw out partial strips when they were done for the day or something. Well let's just say, any time a project required a nail, we knew exactly where to get one!

The biggest problem with installing this flooring material is that it comes in random lengths, at least seemingly random. You can open a box and you'll have a lot of long pieces, and another box will have a lot of short pieces. We would keep three boxes open at a time to be sure to have the variety we needed in order to not end up with two seams matched up from one row to the next, within six inches. This allows the seam of one row to be held tightly by the groove of the next row being complete. This gives the floor strength, and it makes the floor have a much more random look, not repetitive like tile for instance. Finally someone had the great idea to stand it up along the wall and be able to see how long the boards were and find that there were really about seven different lengths, and knowing that you could select the boards you needed much more quickly. Since the board length didn't always add up to exactly the width of the room, we would have to cut a little off the end of one board at the end, and usually use that cut off piece to start the next row, not wasting too much material. Once we got in a pretty good pattern of putting in pieces, tapping them in place with a pounding block (discarded piece of material) and cleat nailing the main floor of the kitchen went pretty fast. Then we got to the counters.

The area under the dishwasher does not get any hardwood. Just the new plywood underlayment. This required that we drew a straight line across where the lower front of the dishwasher would end up and place our boards right on top of this line. There were other special areas, like around the stove and getting back in where the refrigerator sets.

Eventually we had to call it a night since it was 10 o'clock and we had to use a power saw.

We had made it to the entryway to the living room.

The plywood installation completed Saturday morning about 11AM. We had to buy some more plywood, because we just didn't have enough. It turned out that we needed three additional 4x8 sheets of plywood, we originally had 16 making the total 19 sheets used, with a little wasted material trying to fit in special areas etc. (This will be important later, note the foreshadowing)

I uploaded a video of the plywood underlayment stapler in action.

After we completed stapling down the plywood, we put down the tar paper for a moisture barrier. Apparently it also acts to quiet the floor some as well. It is a piece of kraft paper, a layer of tar, and another piece of kraft paper. When you look at the floor in progress pictures, you'll see a greenish/brown paper laying on the plywood underlayment. It is four feet wide and we put down one line of it to start.

The most drawn out part of the day was getting the proper initial measurements to set the first line of boards. Over and over it is emphasized to not use the wall as a guide, rather find a couple of places along the wall and measure out 1/2 of one board width PLUS a 1/2 inch expansion space. In our case that makes 3 inches. However the wall is not straight, and the sliding glass door is set back a little way from the drywall. We marked a few places, then used a chalkline (had to go buy one since I hadn't asked anyone to bring one of theirs) to snap a straight line as a reference. Since the marked points are from the wavy wall, some of them are inside of the line and some of them are outside of the line. The line is the reference for all of the boards along that first row. We then had to measure the actual width that the first board needed to be. Oh man this took a long time, then we made one wrong and had to do it again. The biggest problem is remembering which edge of the board to measure from since there is a tongue on one side and a groove on the other, you can't just turn them around if you measured wrong.

Eventually we had a board cut to the right dimensions to attach it to the floor. Since the first run is usually two or three inches from the wall, the special air-powered wood floor cleat nailer was too big to get in and be used. We had to pilot drill and hammer in 1-1/2" finishing nails. The pilot drill was a nail with the head cut off. Once the first board was nailed down, we could move on to the board next to it. Again, since the wall is wavy, we had to measure again to be sure that the board would end up with about 1/2" clearance from the wall. This space gets covered by "quarter-round" molding eventually. This proceeded for what must have been an hour, maybe more. It may have taken a while, but it was important not to rush it, as any mistake there would offset the next row etc. etc. so I wanted it to be right.

Once the first row was top-nailed, we could actually start using the cleat nailer. Cleats are like a flat nail with an L shaped head. They are designed to be driven at an angle through the tongue end of the board, between the tongue and the top of the board. This holds it solidly, but can be covered up by the groove of the next board. This leaves no nails on the surface of most of the floor.

Seeing these cleat nails in a row like this reminds me of when I was a kid and my dad and I were at a parking lot with a construction site adding on to the strip mall. We looked on the ground and there was a lot of litter, and in the litter there were these strips of nails, all glued together at an angle. We figured it was trash so we grabbed a few strips and took them home. We had hundreds of these nails, apparently the guys using them just threw out partial strips when they were done for the day or something. Well let's just say, any time a project required a nail, we knew exactly where to get one!

The biggest problem with installing this flooring material is that it comes in random lengths, at least seemingly random. You can open a box and you'll have a lot of long pieces, and another box will have a lot of short pieces. We would keep three boxes open at a time to be sure to have the variety we needed in order to not end up with two seams matched up from one row to the next, within six inches. This allows the seam of one row to be held tightly by the groove of the next row being complete. This gives the floor strength, and it makes the floor have a much more random look, not repetitive like tile for instance. Finally someone had the great idea to stand it up along the wall and be able to see how long the boards were and find that there were really about seven different lengths, and knowing that you could select the boards you needed much more quickly. Since the board length didn't always add up to exactly the width of the room, we would have to cut a little off the end of one board at the end, and usually use that cut off piece to start the next row, not wasting too much material. Once we got in a pretty good pattern of putting in pieces, tapping them in place with a pounding block (discarded piece of material) and cleat nailing the main floor of the kitchen went pretty fast. Then we got to the counters.

The area under the dishwasher does not get any hardwood. Just the new plywood underlayment. This required that we drew a straight line across where the lower front of the dishwasher would end up and place our boards right on top of this line. There were other special areas, like around the stove and getting back in where the refrigerator sets.

Eventually we had to call it a night since it was 10 o'clock and we had to use a power saw.

We had made it to the entryway to the living room.

Friday, August 24, 2007

And So it Begins

We started the weekend early, by putting down the underlayment.

The process is pretty straightforward. Starting with a full sheet of plywood lay it down in the farthest corner and then put screws at each corner, and halfway along each edge. Then take the

air powered staple gun and put staples every 12 inches along the edge and every 12 inches midst the field. I bought 2,000 staples, figuring I needed a little more than 1,000. At the end of the night, with only three sheets of plywood to go, I only have 500 left. Guess I am putting in more than enough staples.

The part that really slowed us down was getting the plywood to fit in to all of the areas that the appliances are in. We wanted to have the plywood under the dishwasher, stove and refrigerator, so we had to do some fancy cutting and pushing to get around. One piece covered both the underneath of the stove and the refrigerator, which has a small cabinet between.

After the kitchen was done, we proceeded to the living room. It's a piece of cake compared to the Kitchen, but we realized that we didn't have enough sheets of plywood left. We had used 9 sheets in the kitchen, and had only bought 16, so we certainly didn't have enough to finish. We'll need to pick some of that up in the morning.

Tomorrow, as early as I can get up, we are going go to the local Home Depot and rent the hardwood floor nailer. It is a pneumatic nailer, set at an angle, and fired by hitting it with a certain mallet. The mallet causes the board to snug up to the one next to it before the nail drives home. The unit at Home Depot actually uses something called a cleat. It is a flat nail with barbs along the bottom edge, and an L shaped top. Apparently this is now the "best" way to install floors. Fortunately they have a lot in stock (well at least at 7PM tonight) hopefully they will still have some at 7AM tomorrow.

Gotta get some sleep and get back at it in the morning. My sister flew in tonight, and another friend is coming to help and is bringing his chop saw over to cut the ends square.

The most important part of the day is getting the flooring started square, so it may take us a little while to get it all right before we nail anything down. Hopefully by 10AM we will be laying flooring at a good rate. Check back tomorrow night!

The process is pretty straightforward. Starting with a full sheet of plywood lay it down in the farthest corner and then put screws at each corner, and halfway along each edge. Then take the

air powered staple gun and put staples every 12 inches along the edge and every 12 inches midst the field. I bought 2,000 staples, figuring I needed a little more than 1,000. At the end of the night, with only three sheets of plywood to go, I only have 500 left. Guess I am putting in more than enough staples.

The part that really slowed us down was getting the plywood to fit in to all of the areas that the appliances are in. We wanted to have the plywood under the dishwasher, stove and refrigerator, so we had to do some fancy cutting and pushing to get around. One piece covered both the underneath of the stove and the refrigerator, which has a small cabinet between.

After the kitchen was done, we proceeded to the living room. It's a piece of cake compared to the Kitchen, but we realized that we didn't have enough sheets of plywood left. We had used 9 sheets in the kitchen, and had only bought 16, so we certainly didn't have enough to finish. We'll need to pick some of that up in the morning.

Tomorrow, as early as I can get up, we are going go to the local Home Depot and rent the hardwood floor nailer. It is a pneumatic nailer, set at an angle, and fired by hitting it with a certain mallet. The mallet causes the board to snug up to the one next to it before the nail drives home. The unit at Home Depot actually uses something called a cleat. It is a flat nail with barbs along the bottom edge, and an L shaped top. Apparently this is now the "best" way to install floors. Fortunately they have a lot in stock (well at least at 7PM tonight) hopefully they will still have some at 7AM tomorrow.

Gotta get some sleep and get back at it in the morning. My sister flew in tonight, and another friend is coming to help and is bringing his chop saw over to cut the ends square.

The most important part of the day is getting the flooring started square, so it may take us a little while to get it all right before we nail anything down. Hopefully by 10AM we will be laying flooring at a good rate. Check back tomorrow night!

Subscribe to:

Posts (Atom)